Is 3D printing an environmental win?

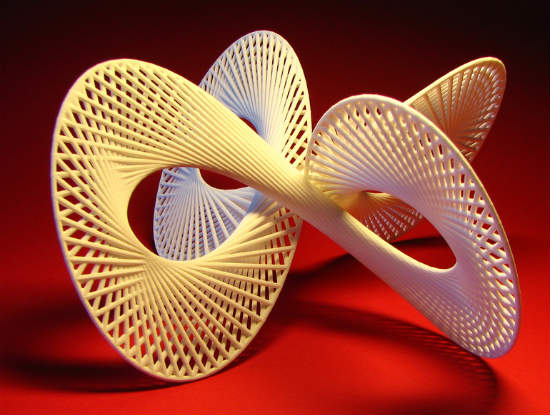

3d-printed object by fdecomite via Flickr

Technophilic环保人士,包括我自己,吹嘘3D打印革命,可以制造消除浪费的福音。但是,这是真的吗?即使这是真的,它比使用额外的能量有关系吗?并且怎么样毒素 - 它释放出更多的,还是少了?

以前没人全面,定量的方式进行这种比较,所以我和同事一起在加州大学伯克利分校机械工程系出发去寻找答案。结果是棘手和令人惊讶的。

首先,让我们胸部的一个神话:3D打印并不意味着零浪费。有许多种3D打印机,使得有很大不同的东西;我们测量两种。一个“FDM”机器(如RepRaporMakerbot, sort of a hot glue gun with XYZ controls), actually can have a negligible percent waste, if your model doesn't need any support material to shore it up while printing. (That's a big "if.") But we found that an inkjet 3D printer (which lays down polymeric ink and UV-cures it layer by layer) wastes 40 to 45 percent of its ink, not even counting support material, and it can't be recycled. Other researchers studying other kinds of 3D printers have found significant waste in some of them as well.

To see whether 3D printing will be a sustainability win, we compared it to machining by a computer-controlled mill (starting with a block of stuff and cutting away everything you don't want). We only looked at machining things out of plastic, because that's what these FDM and inkjet 3D printers do. Let's be clear: most plastic consumer products are not machined; they're injection-molded. But 3D printing is not going to replace injection-molding for mass-manufactured products (plastic parts made in the millions). It is replacing machining for smaller runs (1 unit, 10 units, maybe 1,000 units).

我们做了两个3D打印机和数控铣床的生命周期评估(LCA),包括材料和制造机器本身,交通,能源利用,材料在最后的部分,材料浪费相比它们,并结束betway必威娱乐-of-报废处理的机器。

该研究的一个棘手的部分是,你不能只是比较这些机器的生态影响,每年,甚至是每次使用的时间,因为他们操作如此不同。您可以创建在一个半小时的数控铣床,将采取3小时以进行喷墨打印的一部分。因此,为了使工具之间一个苹果对苹果的比较,我们决定在两个部分中的所有三台机器进行,并计算出的每年每部分的生态影响。

Deciding on the winner was quite a horse race. First, we discovered that it's more about how you use the tools than about the tools themselves — any one of the machines producing a part once a week but left running the rest of the time had about 10 times the environmental impact of the same machine producing parts all the time (as close to 24/7 production as possible). This 10x difference was far bigger than the differences between machines, for most scenarios. So, the best strategy for sustainable prototyping is to share tools: have the fewest number of machines running the most jobs each. In cases like this, job shops legitimately can argue that they provide both economic and environmental advantage to their customers.

一旦您开始使用以高生产速度每一个工具,在FDM打印机是赢家。它比喷墨三维打印机的一半或更少的冲击,而且比周围磨少三分之一。然而,每个机器有很多变化的,这取决于如何每个使用 - 它有助于打印在FDM 90%中空部位,同时用喷墨打印多份,并与开始为原料的小的块尽可能与轧机;它甚至重要的部分是如何为导向。其结果是,喷墨比较与工厂并没有给出一个明确的赢家。喷墨通常得分差,但它被以最高效率运行,整个工厂都没有更好的方案得分。

在FDM的领先优势是更清楚。事实上,当只生产零部件,每周一次,但仍然执行以及喷墨和以高生产速度运行,只要你打开它的数控机床,当你不使用它完全关闭。这是使用爱好者级FDM机器的人,如Makerbots好消息。所有这些快速成型方法比成绩更差注射成型(对此我们只是用库存数据,而不是新的测量),但正如前面提到的,这不是一个公平的比较;我们只把它作为基准。

上面的图表显示了结果single-score"points," fading out at the tops to show the degree of variation in results — each tool may score as well as the bottom of the fading, or may score as badly as the top of the bar, depending on the usage scenario and fundamental data uncertainty. These "points" are a way to compare the apples and oranges of different environmental impacts. Most LCAs of these machines only measure energy use, but that's not enough. For our high-usage scenarios, if we measured only energy use, the milling machine would score the best. But if we measured only waste, the mill would score the worst.

那么,我们如何还算比较这些,以及其他因素,如毒性?我们用所谓的“秘方端点H”的LCA方法是标准化所有这些影响 - 二氧化碳部分公斤的颗粒物每百万,土地等等公顷 - 在同一个单位,然后按照严重性重它们。单分数的方法是这样的完美绝对远,但有一个可信的科学方法来比较不同的影响,从比较这节省了产品设计师,工作店主,原型实验室经理或其他决策者(没有一个人是环境科学家)由没有受过教育的猜测环境和健康影响。为了规避我们的赌注,我们还与其他单一的分数加权系统(IMPACT 2002以上)运行的数字。令人高兴的是,我们得到了相同的结果。

该3D打印机的影响大多是从用电量,这仅仅是时间的函数来了,所以任何减少花费也运行时间减少了生态的影响。该工厂的影响是主要来自材料的使用和浪费,但能源的使用是显著了。的资源和制造,使机器本身是当它们在高温利用率运行,如图上述影响的一小部分;但如果你只让每周一个组成部分,体现的那些影响,可以为FDM和磨显著。

The final verdict, then, is that 3D printing can be greener, if it's the right kind (FDM); but again, the biggest environmental win comes from sharing the fewest tools so each has the most utilization. If you want to know more, the full study (with far more detail in methodology and results, including breakdowns of impacts by source for all 22 scenarios studied) has been submitted to the Journal of Rapid Prototyping. Be patient, though; peer-reviewed academic publications take a year or more to get published.

(非常感谢劳伦斯伯克利国家实验室的联合中心人工光合作用和加州大学伯克利分校的机械工程机械车间的使用他们的工具。)

3D-printed image of Quadrifolium design byfdecomite Flickr网站