为什么西门子,GE和Rolls-Royce转向3D打印

内部的添加剂制造的优点和缺点。

As 3D printing becomes the new norm in manufacturing, many have waxed poetic about its environmentally friendly attributes, positing a green production revolution that minimizes waste.

现实并不是那么简单。虽然现场打印零件或组件可能比某些生产技术更可取,但在许多情况下,它并没有比较有利。

3D printing techniques, however, could be almost universally preferable, if industry steers in the right direction. And clear pathways exist for maximizing the technology’s green potential. A new OECD report,"3D Printing and its Environmental Implications,"examines the technology’s sustainability implications and offers top priorities for policy interventions to address and improve its environmental impact. (See chapter 5 on "The New Production Revolution.") Those changes involve revisions in both printer design and operation strategies.

绿色不是已定局的结论

3D打印(也称为加法制造)是从数字文件中制作三维实体对象的过程。打印机仅在需要的情况下仅在需要的情况下添加连续的材料层,直到创建三维对象。每一层都可以看作是最终对象的薄片。3D打印技术自1980年代以来就已经存在,但是直到过去十年中,关于其破坏性潜力的讨论才引起了人们的关注。研究公司统计数据的数据大小3D printing market2017年约88亿美元,预计到2019年的收入将达到160亿美元。

Despite many people’s assumptions, 3D printing is not inherently greener than other manufacturing methods. In fact, it includes many methods of printing, most of which cause worse impacts than injection molding of plastic at scale, because 3D printing consumes more energy and often generates more waste. On the other hand, 3D printing manufacturing techniques usually have a比加工较小的环境足迹(PDF)。

一些公司在3D打印的潜力上大量投注,以及开始实现一些环境利益。

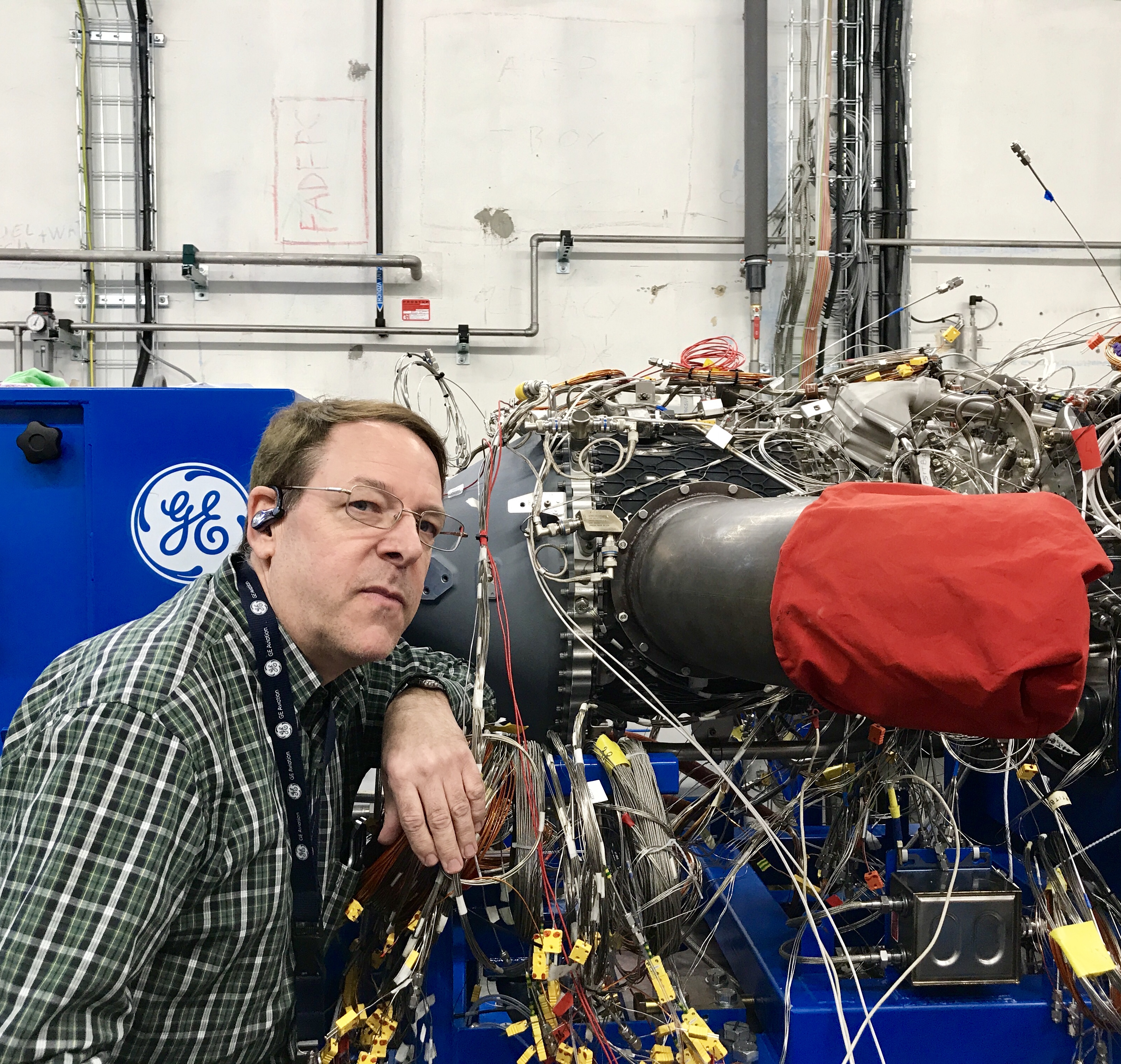

西门子已经推出了产生较少高价值浪费的产品,并可以更快,更有效地更换敏感的备件 -例如工业气体发动机的涡轮机- 与其他制造技术相比,还可以。劳斯莱斯(Rolls-Royceshapes it produces with 3D printers无法创建任何其他方式。和GE has used 3D printingto achieve improved durability for extended product life, improved fuel efficiency during product use, and simplification and dematerialization of products. In 2016, it spent more than $1 billion to buy controlling stakes in two leading industrial players — citing the substantial potential to cut costs.3D打印会消耗更多的能量,并且通常会产生更多的浪费。另一方面,这些技术通常比传统加工更小。

"Today, there are hundreds of big planes flying between cities around the world and carrying machine components," said Mohammad Ehteshami, who runs the GE Additive business, in公司报告关于11月的小组。“明天,您将不需要所有这些。您只需打印所需的内容即可。”

这些例子令人鼓舞,但它们也很出色 - 由具有强大的环境承诺和专业知识的公司驱动。当涉及3D打印的整体环境性能时,仍有许多待发展和理解。

In November, Yale published aspecial issue of its Journal of Industrial Ecology, presenting the latest research on 3D printing and providing insights into its environmental, energy and health impacts. GE was one of the primary funders of the free issue.

“本期的研究表明,将3D打印标记为可持续制造的途径还为时过早,”saidReid Lifset,《工业生态学杂志》的总编辑和主社论的合着者。“我们需要更多地了解材料足迹,生产的能源消耗,流程排放,尤其是生产过程中各个阶段之间的联系和对齐。”

A kinder, gentler 3D printing

OECD报告比较了多个可持续性属性的多种3D打印技术,并列出了每个可持续性的利弊。必威体育2018报告作者杰里米·法鲁迪(Jeremy Faludi)预测,这项技术将在未来几十年中占主导地位,因此3D打印的环境概况对于理解和管理至关重要。该报告提供了使3D打印更绿色的具体建议,包括:

- 减少3D打印的能源消耗:Transitioning from processes that melt plastics or metals to non-toxic chemical bonding techniques substantially would reduce 3D printing’s energy requirements. Energy use causes the largest portion of 3D printing’s environmental impacts.

- 最大化打印机共享:Ideally, 3D printing would follow the FedEx/Kinko’s model, rather than mimicking the printer-on-every-desktop scenario that has developed for document printers. Ecological impacts per printer part can be 40 times greater for a printer producing one part per week and left powered on the rest of the time, than for a printer that is actually printing parts nearly 24 hours per day every day.

- 为循环经济采用可堆肥生物材料:betway必威体育手机版不可分割地打印混合材料可能变得越来越普遍,并且在经济上处理该材料是通过堆肥来处理的。对于某些3D打印机类型,可堆肥生物聚合物已经存在,但是选项仍然有限,并且最受欢迎的生物塑料(PLA)在大多数市政系统中均未堆肥。对于其他打印机类型,可堆肥的生物材料只是研究项目。经合组织报告建议开发以扩大可堆肥生物材料的市售选择,并提高其身体绩效和成本。

Designing a better world

3D printing stands poised to shift industrial manufacturing methods dramatically away from traditional technologies, and in the Marxist sense it broadens access to the means of production.

While widespread 3D printing would not automatically be an environmental benefit as practiced today, technologies already exist that, if brought from the research fringes to status quo, could shift manufacturing towards significantly more sustainable production.

随着添加剂制造业处于十字路口,有针对性的政府和公司政策可以将其启动,以使人类和地球在未来几十年中受益,而不是复制当前制造系统的问题。稍作谨慎,3D打印可以帮助我们建立一个更美好的世界。